正在下载文件,请勿关闭页面,若关闭页面下载任务将会取消

1、 Product positioning and core values

SN-2200CN is a high-precision digital torque tool that focuses on the needs of "precise torque control+convenient operation". Through real-time digital display, intelligent alarm and data tracing, it solves the pain points of traditional wrench torque ambiguity and large errors. It is suitable for scenarios such as automotive maintenance, mechanical assembly, equipment operation and maintenance that require strict torque accuracy, ensuring assembly quality and safety.

2、 Basic parameters

Project Details

Model SN-2200CN

Weight 2.524kg (lightweight design, balancing durability and effortless operation)

Dimensions: 74 × 14 × 7.5cm (total length suitable for regular operations, compact structure)

3、 Structural analysis (based on graphic design, with strong functional reusability of components)

(Reference question stem diagram logic, unified design of component names and functional continuity)

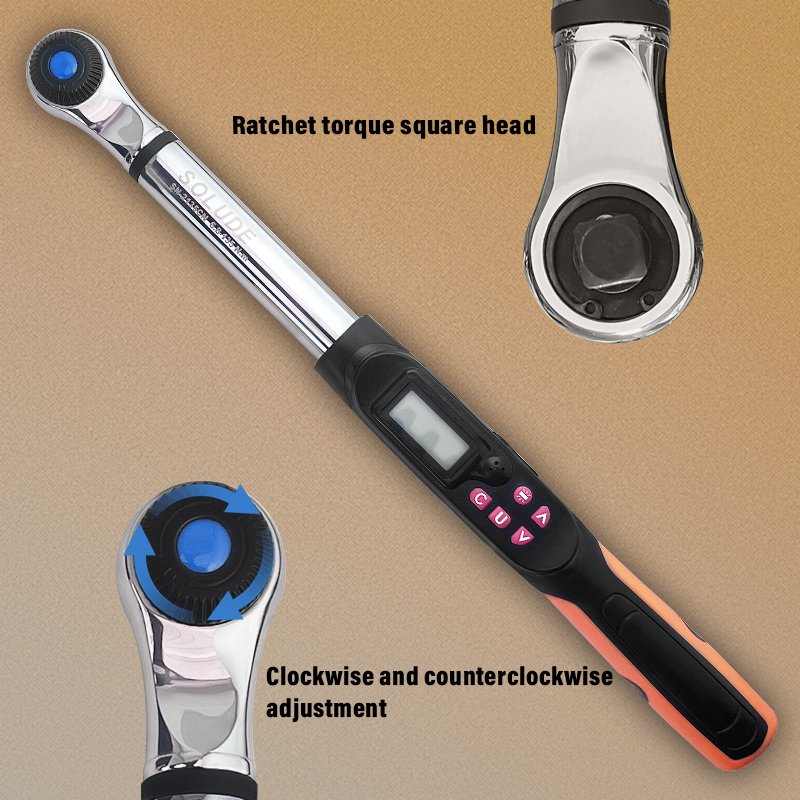

Head system:

Double sided ratchet head+ratchet torque square head: compatible with dual specifications, covering multiple types of bolts, flexible switching, and improved job compatibility.

Central functional area:

Direction paddles: One click switch for forward/reverse, suitable for different fastening directions, with high operational efficiency.

Large LCD screen: high-definition display of torque values, units, and working modes, clear visibility in low light environments, and real-time monitoring of torque status.

Communication port: Supports torque data export (such as connecting to computers/mobile devices) for quality analysis and traceability, and is compatible with digital production lines.

Buzzer: When the set torque is reached, it will sound and light dual alarms (beep+screen display prompt) to avoid human error and enforce standardized operation.

Operation buttons (C/U/V, etc.): Implement functions such as mode switching, unit conversion, data storage/clearing, etc., with convenient interaction.

Tail and handle:

Battery cover: quick release design, easy to replace battery, ensuring continuous operation; The built-in battery has stable battery life (specific parameters are specified in the manual).

Anti slip handle: Ergonomic curved design, comfortable grip, reduces fatigue from prolonged operation; The surface anti slip texture enhances grip stability.

4、 Core functional highlights

Precise torque control:

The accuracy reaches ± 1% (within the full range), ensuring that each tightening strictly meets the standards and avoiding the risk of "over tightening, fracture, under tightening, and loosening".

Multi mode adaptation:

Real time mode: dynamically display applied torque, adapt to debugging scenarios, and monitor the entire tightening process.

Peak mode: Record the maximum torque during the tightening process for easy review of key nodes afterwards.

Preset mode: Set the target torque, automatically sound an alarm when it meets the standard, and enforce standardized operating procedures.

Flexible switching of units:

Supports switching between N · m, ft · lb, kgf · cm units, covering metric/imperial standards, and adapting to torque specifications in multiple industries such as automotive, aviation, and home appliances.

Data management:

Built in storage module, capable of recording multiple sets of torque data; Combining communication functions to achieve data export and information management, assisting in quality traceability and process optimization.

Durability and reliability:

The main body is made of chromium vanadium alloy steel, which is impact resistant, corrosion-resistant, and stable and reliable in dealing with complex working conditions such as oil pollution/vibration; The internal sensors have undergone rigorous calibration, resulting in low precision degradation over long-term use.

5、 Typical application scenarios

Automotive aftermarket: Tire bolts, brake calipers, engine accessory torque calibration, in line with original factory maintenance standards.

General mechanical assembly: Precision assembly of equipment such as pumps, valves, motors, and reducers to ensure stable operation.

Smart home manufacturing: Assembly of core components such as air conditioning compressors and washing machine motors to enhance product lifespan.

Equipment operation and maintenance: Reinstall key screws of industrial production lines and engineering machinery, accurately control and maintain quality.

Verification Code

The file is downloading, please do not close the page.

Digital Torque Wrench SN-2200CN

- SN 2200CN